The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement

©2024 Copyright - BlastTac. All Rights Reserved.

Blastac is the world’s leading blast curtain for good reason, no other product offers the level of protection or the extensive testing to prove it. The entire line of Blastac Curtains and Blankets are tested UL752 tested to levels 1, 2 and 3 in bullet resistance as well as (EN) FB/BR4. Similarly, our blast curtains and blast blankets are also frag tested to: 2-GRAIN RCC V50 BL(P), .22-CAL 17-GRAIN FSP V12 V50 BL(P) and .30-CAL FSP V50 BL(P). Blastac is engineered using DefenseCor™ and AmourCore™ technology, which significantly reduces back-face trauma and also eliminates the need for layer counting, quilting and lamination resulting in a lightweight and superior product.

For high-temperature applications, BlastTac created FireMax. FireMax may be added to any of the products in the Blastac line. FireMax products can provide, thermal, arc flash, chemical and fire protection and may be customized to specific specifications or applications. Using FireMax® technology, Blastac blankets and curtains can be rated for Arc Flash Protection to CAT IV with Arc Flash Rating of 40kA, ASTM F2676. FireMax is truly non-flammable as they will not burn, melt, or ignite and will remarkably shed molten metal, certain chemicals, flammable liquids and other molten substances. The custom woven fabric is lightweight, flexible and odor resistant. FireMax is tested and certified to ASTM and NFPA standards and independent testing from ArcWare, Home Innovation Research Labs, Kinectrics and SpaceX.

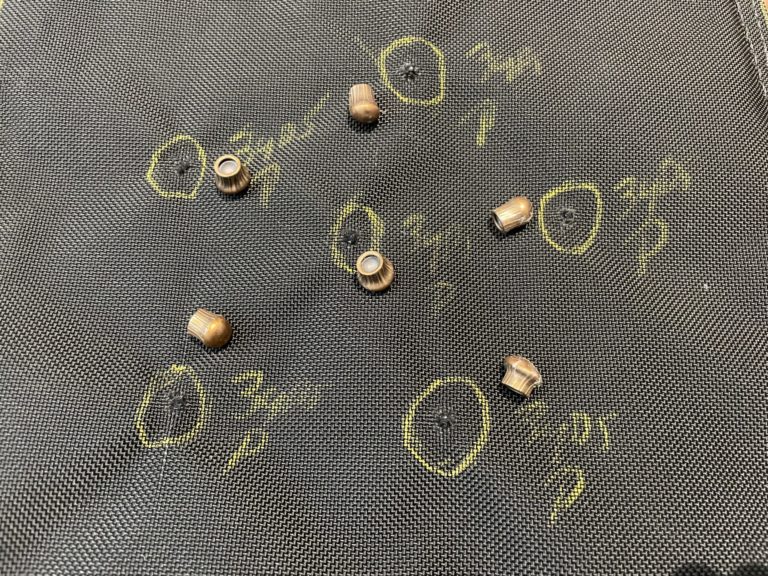

Blastac Curtain, 6 shots at 3yds inside a 15mm circle, 9mm 115gr. All 6 shots stopped.

SIMPLY PUT, IF YOUR BLAST CURTAIN OR BLANKET CANNOT STOP A BULLET IT CAN’T STOP HIGH SPEED SMALL FRAG.

Our ballistic curtains are tested to ballistic international standards including: NIJ, EN1063 BR1-BR4 standards and UL752. We also offer a variety of standard options and custom engineered designs with features including:

Finite element analysis (FEA) is the process of simulating the behavior of a curtain or assembly under given conditions so that it can be assessed using the finite element method (FEM). FEA is used by our engineers to help simulate physical phenomena and thereby reduce the need for physical prototypes, while allowing for the optimization of components as part of the design process of a project.

FEA uses mathematical models to understand and quantify the effects of real-world conditions on a part or assembly. These simulations, which are conducted via specialized software, allow engineers to locate potential problems in a design, including areas of tension and weak spots. With the use of mathematics it is possible to understand and quantify structural or wave propagation, thermal transport and other phenomena.

Most of the processes can be described using partial differential equations (PDEs), but these complex equations need to be solved in order for parameters such as stress and strain rates to be estimated. FEA allows for an approximate solution to these problems. FEA is the basis of modern software simulation software, with the results usually shown on a computer-generated color scale.

Breton Industries is an ISO 9001:2015 manufacturing facility. Our blankets and curtains are constructed to military grade standards using U.S. made materials and manufactured at our facility in Amsterdam, NY. Breton Industries, Inc. is Berry Amendment Compliant has been a U.S. Military Contractor since 1949. Our military experience is the driving force behind the careful design and manufacturing of the world’s finest blast blankets and blast curtains.

Monday-Friday: 8:00-4:30

Saturday: Closed

Sunday: Closed

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement